Thousands of 3D-printed face shields are being produced by De Montfort University Leicester (DMU) to help hospitals across the city protect their staff against the coronavirus.

As shortages of personal protection equipment (PPE) amid the COVID-19 pandemic continue to make the headlines, experts at DMU are using the university’s 3D printers to make plastic face shields to help keep healthcare workers in Leicester safe.

An example of the face shields being printed at DMU

The single-use face shields, which will be donated to University Hospitals Leicester (UHL), have been manufactured to meet minimum specification of NHS-approved standards, using a 3D-printed frame and other components to provide a high level of protection and ensure a comfortable fit for the wearer.

Dr Karthikeyan Kandan, Senior Lecturer in Mechanical Engineering at DMU, is leading the project alongside colleague Dr Farukh Farukh, also a Senior Lecturer at the university's School of Engineering and Sustainable Development.

“We’ve seen in the news that doctors, nurses and healthcare assistants still don’t have access to enough PPE and we want to help in any way that we can,” said Dr Kandan.

“The lack of PPE has been a major concern throughout the pandemic – we have even seen NHS staff making their own masks and re-using equipment.

“Supply chains are under immense pressure to provide resources. While the university campus is closed to students, it makes sense that our printers are put to good use to help address the shortage of PPE.”

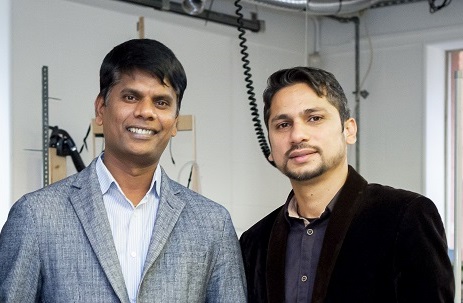

DMU experts Dr Kandan and Dr Farukh

In response to the coronavirus pandemic, the global 3D printing community have developed a range of designs for 3D printable frames which can be used to manufacture face shields.

However, many of the designs would take anywhere between one and five hours to print per frame.

“We simplified the design so that we can make more face shields in less time and we are now able to 3D print a face shield in 20 minutes,” continued Dr Kandan. “By doing this, we can print hundreds of the shields in a day to meet the urgent demand in the healthcare sector.”

The team has also purchased face shield kits that can be assembled quickly to meet urgent demand. These comprise a visor, foam pad and elastic that are certified with a CE-mark – meaning they meet the regulatory requirements needed to legitimately offer a PPE product on the European market.

Dr Kandan added: “In addition to 3D printing our own designs, we can use these approved kits to rapidly manufacture even more face shields.”

COVID-19:

* How students and staff at DMU are supporting the community at this time

* Advice and information on COVID-19

* Scientists advise Government that no healthcare uniforms should be washed at home during COVID-19 crisis

Virus expert Dr Maitreyi Shivkumar, a lecturer in Molecular Biology at DMU, said plastic face shields were a useful way to reduce transmission of COVID-19.

“The SARS-CoV-2 virus is transmitted via respiratory droplets containing infectious virus produced during coughing or sneezing,” explained Dr Shivkumar. “Healthcare workers coming into close and prolonged contact with COVID-19 infected patients are at a high risk of acquiring the virus from respiratory droplets.

“Plastic face shields serve as a physical barrier to prevent large droplets hitting the wearer's face, mouth, nose and eyes, and therefore contributes towards reducing transmission of the virus via infectious respiratory droplets.”

Posted on Monday 4 May 2020