Podium presentation at the ISL-FD conference in Havana, Cuba

Geoff Smith gave one of the talks at the 8th International Conference of The International Society for Lyophilization and Freeze‐Drying (ISL‐FD Inc.) that was held in La Habana, Cuba on April 24-29th 2017.

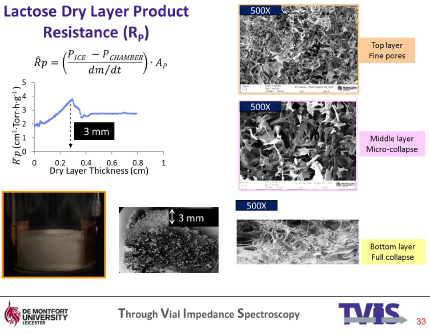

In his talk, entitled Recent Advances in Through Vial Impedance Spectroscopy (TVIS) for Process Parameter Determination he explained how the technology could be used to predict the product temperature (and hence the partial pressure of ice at the sublimation interface, Pi) while measuring the primary drying rate (dm/dt). From Pi and dm/dt the dry resistance to vapour flow (Rp) can be calculated and monitored through the drying stage. In one of the experiments reported, the shelf temperature (and hence product temperature) was increased in order to force the product to a micro-collapse. The below slide shows the steady increase in the resistance to vapour flow (Rp) up to a dry layer thickness 3 mm (as the intact dry layer develops). After 3 mm the product temperature has exceeded the collapse temperature and the micro-collapse of the product causes a dramatic drop in the dry layer resistance. Note that the final value of Rp is not lower than the initial value owing to the fact that there is a skin on the dried material which maintains the dry layer resistance at a reasonable level.